On August 5, 2015, an Environmental Protection Agency (EPA) remediation project resulted in the release of three million gallons of polluted mine water into Cement Creek, a tributary of the Animas River, near Silverton, Colorado.

In the absence of information from the EPA about the events that actually lead up to the release of contaminated mine water from the Gold King 7th Level Adit, I published an article on August 18, 2015. “Anatomy of the Gold King Mine Spill – Was it Caused by an Ice Plug?” examined the sequence of events, which lead up to the spill that occurred at the Gold King mine on August 5, 2015 and analyzed the role these actions played in this release.

Since that date the EPA has been more forthcoming with information about the release of contaminated water from the Gold King mine. While information contained within their August 24, 2015 Summary Report and other news releases has been useful in understanding the events and decisions that lead up to the Gold King blowout, there are many important questions that remain unanswered.

This article provides the public an independent constructive analysis of the EPA’s Internal Review of the Gold King Blowout, identifies technical and management practices that may have enabled or contributed to the spill and discusses procedural alternatives that could be used to minimize the risks encountered in similar situations at other abandoned mines throughout the west.

Geological Setting

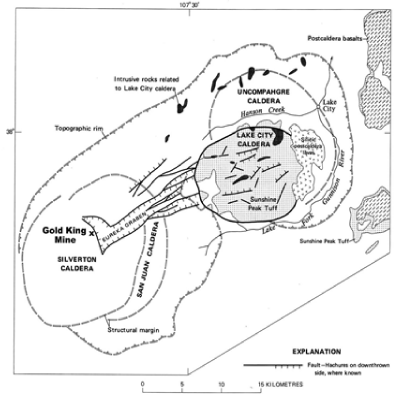

The Silverton-Lake City area is located in the western portion of the San Juan Volcanic Field of southwestern Colorado, which represents a large nested caldera complex, shown in Figure 1.

The earliest volcanic activity commenced about 35 million years ago with the formation of scattered andesitic stratovolcanoes. Over the next 5 million years, a thick sequence of interleaved andesitic lavas, breccias, mudflows and volcaniclastics were deposited around these eruptive centers to form a thick shield, which presently comprises approximately two thirds of the extrusive lithologies in the San Juan Mountains. Sub-volcanic monzonitic stocks and related radiating andesitic and rhyodacitic dikes were emplaced into the cores of the stratovolcanoes about 30 to 32 million years.

Approximately 30 to 26 million years ago, the character of the volcanism evolved to one of voluminous pyroclastic eruptions of silica-rich ash flow tuffs. This resulted in the development of a large nested caldera complex in the western portion of the San Juan Mountains, which includes the Uncompahgre (28 million years), San Juan (28 million years), Silverton (27.5 million years) and Lake City (22.5 million years) calderas. Other collapse structures developed during this period include the northeast trending Eureka Graben (22.5 to 27.5 million years), which connects the Silverton and Lake Valley calderas (Slack and Lipman, 1979).

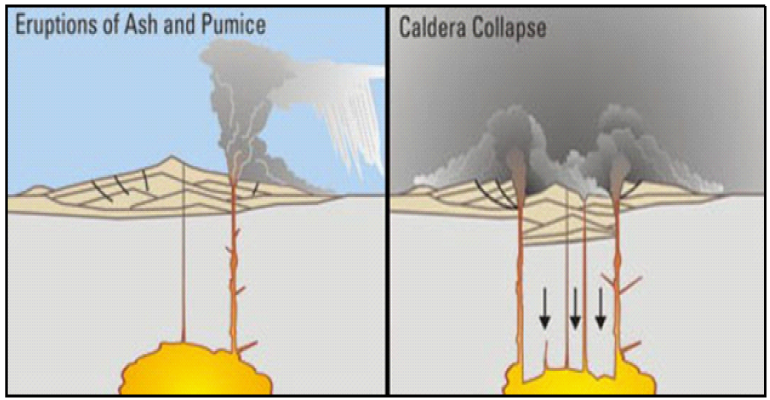

A caldera is formed by a major eruption of an enormous amount of magma from a stratovolcano in the form of voluminous pyroclastic flows and ash (see Figure 2). As magma is erupted, a ring fracture is developed around the summit of the volcano, which eventually collapses into its underlying magma chamber. A nested caldera complex is composed of several overlapping calderas that have developed over a period of time.

Approximately 23 million years ago, the character of the volcanism changed to the extrusion of volumetrically minor flows and tuffs of a bimodal basaltic-rhyolitic assemblage, known as the Hinsdale Formation (5 to 23 million years). Most of the coeval intrusive bodies (10 to 26 million years) of intermediate to silica-rich composition in the San Juan volcanic field were emplaced along pre-existing structural zones in and around the caldera margins.

Base metal-gold-silver ores (10 to 16.6 million years) at the Sunnyside and Gold King mines generally occur along steeply dipping faults and fissures associated with northeasterly striking structures of the Eureka Graben. These mineralized structures cut late Oligocene to early Miocene rhyodacitic to quartz latitic flows, breccias and pyroclastics (Casadevall and Ohmoto, 2008; Koch and others, 1988). The northeast striking veins pinch and swell along strike and with depth and have widths that range from 2 to 22 feet. Ore-bearing minerals include gold, sphalerite, galena, chalcopyrite and tetrahedrite-tennanite with associated pyrite. The gold mainly occurs in its native state and is alloyed with up to 35% silver. Vein gangue minerals include quartz, rhodochrosite, fluorite and calcite (Rosemeyer, 1988).

The oxidation of pyrite and other sulfides exposed within the underground mine workings is what produced the mustard-colored, metal-bearing, acidic mine water that was discharged from the Gold King mine.

Mining Operations

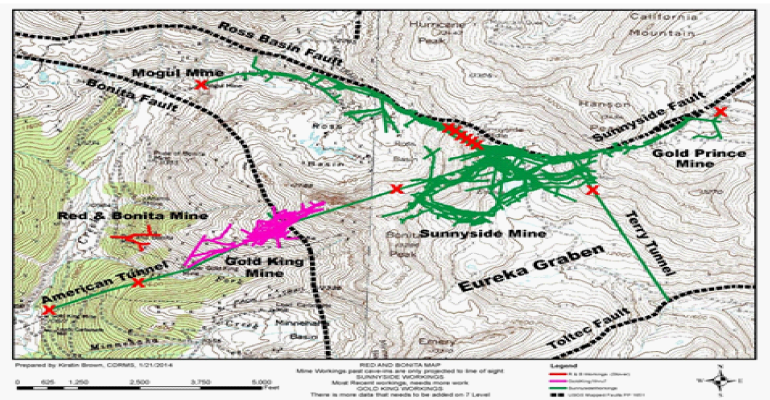

The Red and Bonita mine was initially developed in 1897 and produced a small amount of ore before operations were suspended in 1900 (see Figure 3). It is a small mine with approximately 3,500 feet of mine workings located on a single level. Its portal is located at an elevation of 10,893 feet (EPA, 2015a).

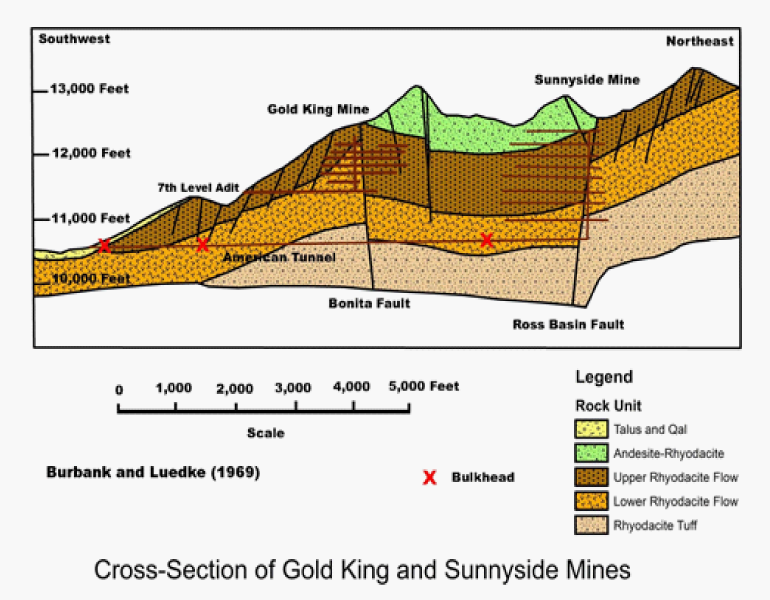

Discovered in 1887, the Gold King mine was operated from 1896 until the fall of 1922. It consists of numerous underground workings located on seven levels extending from an elevation of 11,440 feet to approximately 12,300 feet (Burbank and Luedke, 1969). The Gold King mine has had no maintenance since 1991 and has not been accessible since the 7th Level Adit collapsed in 1995. The Gold King 7th Level Adit (elevation – 11,440 feet) is the location, where the August 5th spill occurred.

Initially discovered in 1873, the Sunnyside mine was the largest producer in the area. It was active during two periods from 1875 until 1938 and 1959 until 1991. Sunnyside was a very large mining operation with numerous underground workings extending from an elevation of approximately 10,660 feet to just over 13,000 feet. It has two haulage/drainage tunnels – the Terry Tunnel (portal elevation – 11,554 feet) and the American Tunnel (portal elevation – 10,589 feet) (Burbank and Luedke, 1969). The American Tunnel lies approximately 800 feet directly beneath the Gold King underground mine workings.

The Terry and American drainage tunnels were very effective in dewatering adjacent rock units over a large region above the level of these tunnels. This method of dewatering underground mine workings was commonly used by historical operations including the Sutro Tunnel at the Comstock Lode in Nevada, the Ontario Tunnel at Park City, Utah and the Yak Tunnel at Leadville, Colorado. The use of drainage tunnels is currently discouraged at new mining projects, because can result in unacceptable levels of acid mine drainage after water and oxygen contact pyrite-bearing rock, is prone to large uncontrolled releases of mine water and complicates reclamation efforts.

Reclamation Efforts at Sunnyside Mine

In accordance with the Clean Water Act, the Sunnyside mine operated a water treatment plant at Gladstone (i.e. portal of the American Tunnel) since the 1970s. Following the Sunnyside mine closure in 1991, twelve bulkheads were installed as a part of decommissioning and reclamation efforts, which evolved over a period of approximately two decades through negotiations between the Sunnyside Gold Corporation, State of Colorado and adjacent mine owners.

As a part of this effort, the water treatment plant at Gladstone continued to treat drainage from the American Tunnel. Following the installation of the final bulkhead at the portal of the American Tunnel, Gold King Mining, Inc. acquired the Gladstone water treatment plant from Sunnyside in early 2003. Water treatment operations were suspended a short time later due to financial and technical problems.

Bulkheads are engineered dams placed within underground passageways, which are designed to contain acidic mine water in the mine as the regional groundwater table returns to its natural, pre-mining level.

In theory, once the underground workings are submerged by groundwater, the inundated portions of the Sunnyside mine will be denied oxygen. This halts the oxidation process, which can produce acidic mine water that contains elevated levels of dissolved metals. As the regional water table is restored to relatively stable, pre-mining levels, the concentration of dissolved metals in the water will be diluted by fresh water moving inward towards the dewatered area through fractured bedrock along pre-mining groundwater courses. Once the water level reached equilibrium at the Sunnyside mine, the acid content of the mine water was further neutralized by injecting 652 tons of lime into the flooded mine workings (Thompson, 2015). Reduction in acidity through the use of lime and natural dilution will result in the precipitation of much of the heavy metal content in the water prior to being discharged at springs or into streams.

However, this approach requires all adits that intersected the pre-mining water table to be plugged. Otherwise, groundwater may rise to the level of the portal at another underground mine and discharge water that has been contaminated within those mine workings into the environment.

Regional Hydrology

No mine workings directly connect the American Tunnel with the overlying Gold King or Red and Bonita mines (see Figure 4). The water table in the vicinity of these underground workings was lowered as a result of drainage into the American Tunnel through numerous natural fault (i.e. Bonita Fault) and fracture zones that cut the rocks where the underground workings are located.

While the Sunnyside mine was in operation, there was very little if any drainage from either the Gold King 7th Level Adit or the Red and Bonita mine because the water that would have otherwise accumulated within these workings was drained by the American Tunnel. However, not long after the three bulkheads were installed in the American Tunnel (1996-2002), drainage from the Red and Bonita mine (pH of 5.5 to 6) and the Gold King 7th Level Adit (pH of 2.5 to 5) rose to 200 to 300 gallons per minute and 50 to 300 gallons per minute, respectively (EPA, 2015a; 2015c).

Following the installation of the last bulkhead in the American Tunnel, water flow from the American Tunnel decreased to less than 100 gallons per minute and the treatment of water discharged from the American Tunnel and Cement Creek was discontinued shortly thereafter. The quality of water in the Animas River has progressively declined since that time due to increased flows from the Red and Bonita and Gold King mines.

This is comparable to a bathroom sink that has a drain and an overflow outlet. When the drain (i.e. American Tunnel) is open the water flows out the bottom of the sink. However, if you close the drain (i.e. with a bulkhead) the water will rise in the sink until it gets to the overflow outlet (i.e. Red and Bonita mine and Gold King 7th Level Adit).

Red and Bonita Mine Remediation Program

The EPA’s work at the Red and Bonita mine site began in 2010, where the historical adit had been collapsed or covered for an unknown number of years. At that time acid mine drainage was leaking through this debris at a rate of 200 to 300 gallons per minute and flowed into Cement Creek.

The initial phase of the Red and Bonita reclamation program involved drilling a vertical hole into a void in the adit/tunnel behind the blocked portal to monitor the impounded water within the adit in order to determine if it was under hydraulic pressure from a possible water pool within the mine workings. Once it was determined it was safe to proceed, the EPA contractor removed the debris that was blocking the portal and the water within the adit was pumped from the mine and treated prior to being released into Cement Creek.

A new, stable mine portal (adit entrance) was installed in October 2011 (Schmidt, 2012). This enabled workers to safely enter the mine to gather data required to determine the best way to stem the flow of acidic mine water from the historic workings. Results of this study indicated the most favorable place to locate a bulkhead is approximately 265 feet from the mine portal (Way, 2014). Installation of the reinforced bulkhead with a valve that will provide hydraulic control was scheduled to occur during the summer of 2015.

Gold King Remediation Program

The EPA has been evaluating the Gold King site for approximately four years. During the 2015 field program, the EPA planned to remove debris from the collapsed or covered Gold King 7th Level Adit in order to observe possible changes in the discharge resulting from the installation of the Red and Bonita mine bulkhead. However, unlike the program at the Red and Bonita mine, their work at the larger, more complex Gold King mine was apparently not as thoroughly planned or well executed.

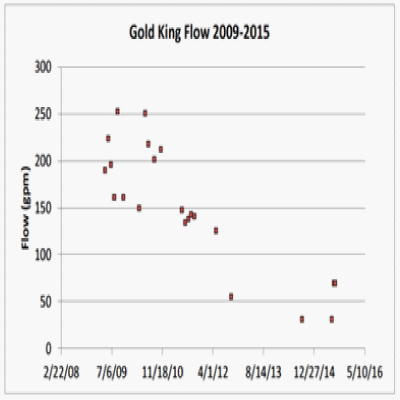

The flow rate of acid mine drainage from the Gold King 7th Level Adit has declined since 2009 (see Figure 5). This might indicate water was accumulating within the mine workings and not draining. However, other interpretations of this data suggest it could be attributed to reduced annual precipitation (i.e. decreased infiltration of surface flow into the workings via fractured, faulted, or broken rock) or increased flows from the American Tunnel owing to ineffective bulkheads.

A superficial examination of the site by the EPA and reclamation contractor on the day of the release suggested the probability of a buildup in pressure behind the material blocking the portal was low based on the absence of seeps on the hillside above the 7th Level Adit and observed drainage from the blocked mine portal. The inconclusive historical flow rate data from the mine suggested that this might not be the case. With limited information available on which to base their judgment, the EPA decided to proceed with the removal of the debris from the Gold King 7th Level Adit on August 5, 2015.

In their internal review of the Gold King Blowout, the EPA states: “the inability to obtain an actual measurement of the mine water pressure behind the entrance blockage seems to be a primary issue at this particular site” (EPA, 2015c).

Considering the size and complexity of this underground mine and the potential risks for a large spill, the EPA should have deferred their decision to proceed with remediation efforts until more conclusive data were available about the amount of water impounded in the mine.

The EPA concedes mine water pressurization data from the tunnel behind the blockage could have been obtained by drilling a hole from above the level of the mine tunnel. This technique had been successfully employed at the Red and Bonita mine in 2010. However, the EPA decided not to use this approach at the Gold King mine due to the steep terrain and instability of the slopes above and in proximity of the 7th Level Adit. Attempting to hit a target such as an adit or a tunnel would have been challenging, time consuming and an expensive process if the drill pad could not be located in close proximity of the adit entrance. It would have required significant resources, considerably more planning and potentially multiple field seasons to implement (EPA, 2015c).

At this point there are number of questions that remain unanswered. When was the decision not to drill above the 7th Level Adit of the Gold King mine made? At what level within the EPA organization was this decision made?

Did the time required to implement a drilling program or the cost of such an effort contribute to the decision not to drill a hole into the tunnel behind the debris covered adit?

Were the on-site personnel provided adequate financial and technical support to safely accomplish their job?

Was there a risk assessment made on the possible consequences that might result from removing of the barrier blocking the adit without first determining the amount of water contained within the mine? If so, what were the conclusions of this risk review?

Discussion

I disagree with the EPA’s assessment that it was not feasible to use a drill hole to obtain data on the level of water impounded behind the blocked 7th Level Adit of the Gold King mine. Track-mounted rotary drill rigs designed to operate on steep slopes with little or no site preparation could have been employed to collect the necessary data at a reasonable cost (see Figure 6). This task could have been completed in a couple of weeks after the driller was secured and mobilized to the site.

The quality of maps of underground workings in many historic mines make it challenging to intersect a mine tunnel from the surface. The 7th Level Adit at the Gold King mine, however, was only 50 to 150 feet below the surface of the slope immediately above the portal.

In 2010, 33 trapped miners in the San José mine near Copiapó, Chile were rescued after drill rigs were used to access underground mine workings at a depth of 2,257 feet. Although poor mine maps also complicated this rescue effort, the eighth hole penetrated mine workings 65 feet from the underground emergency shelter where the trapped miners had taken refuge.

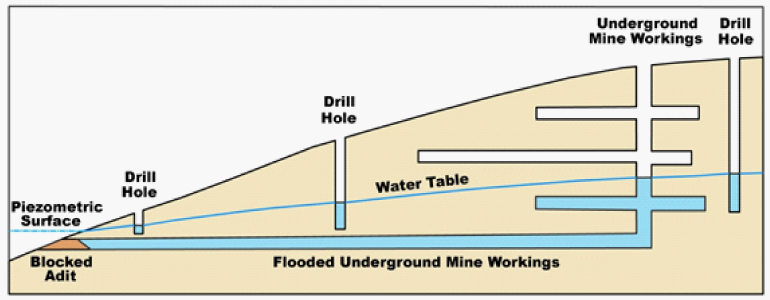

Taking this approach one step further, the drill hole does not have to actually intersect the underground mine workings to get the necessary data. All it needs to do is penetrate the groundwater table near the underground workings. Hydraulic principles dictate both the drill hole and the flooded mine workings will intersect the groundwater table (see Figure 7).

A hydrologic study of this type should include a sufficient number of drill holes to determine what is happening within the underground mine. In this case, six to ten strategically placed, vertical drill holes located in the area of interest should be satisfactory, unless complicating factors are encountered. These drill holes should be installed with perforated casing, so the water levels in the holes can be monitored over time. This data can be used to produce a contour map of the water table in the vicinity of the underground mine workings. When integrated with data obtained from maps of the underground mine and other information (i.e. geologic maps), it is possible to make a rough estimate of the amount of the water contained within the underground mine workings. The water level data can also be useful in understanding what is happening within inaccessible underground mine workings (i.e. cave-ins or internal plugging) as well as natural barriers (i.e. impermeable fault zones) that may be present.

This knowledge can be used to design an effective remediation program at the abandoned mine site and is absolutely necessary to prepare an adequate safety and contingency plan to deal with potential unexpected releases of contaminated mine water during the remediation efforts.

While drilling appears to be the best and most cost effective way to determine water levels within an abandoned mine, other remote sensing tools such as seismic or possibly ground penetrating radar may prove to be more useful in mapping underground mine workings or identifying cave-ins or internal blockages within these passages.

Conclusions

Removing debris from a portal on the lowest level of a mine without first determining how much water is present within the mine is a poor operating practice. The reclamation contractors are working in potentially unsafe, hazardous conditions, and downstream communities are at risk of contamination. Without a full understanding of the situation, a blowout is likely inevitable once removal of the barrier from the portal has commenced. If it hadn’t happened at the Gold King mine, it would have eventually occurred at some other abandoned mine remediation project. It’s like playing Russian roulette. At some point a situation like the one encountered at the Gold King mine on August 5, 2015 will occur. It was just a matter of time.

Collection and analysis of scientific and engineering data is vital for safe and successful remediation efforts at our nation’s mines. Better characterization of the post-mining site conditions through use of a targeted drilling program and hydrogeologic modeling would most likely have identified the unforeseen issues that lead to the uncontrolled release of contaminated mine water from the Gold King mine on August 5, 2015.

A more robust risk review process, including technical review of the data by qualified mining and hydrogeology staff would have greatly improved the contingency planning process and required the reclamation contractors to prepare for more than a dribble of water in a potential blowout.

Although the taxpayer will likely not tolerate making every reclamation project an extensive and expensive university dissertation-level study, some minimum threshold of data collection should be undertaken to support the reclamation design and ensure the safety of reclamation workers and downstream communities. The minimum threshold required should be made on a case by case basis, depending on the size and complexity of the specific project.

Collaboration with universities through funded field research and monitoring programs may be possible to supplement data collection efforts of state and federal agencies charged with overseeing the remediation of the nation’s historical mines.

References Cited

Burbank, W. S., and Luedke, R. G., 1969, Geology and Ore Deposits of the Eureka and Adjoining Districts San Juan Mountains, Colorado: U. S. Geological Survey Professional Paper 535, 73 p.

Casadevall, T., and Ohmoto, H., 1977, Sunnyside Mine, Eureka Mining District, San Juan County, Colorado; geochemistry of gold and base metal ore deposition in a volcanic environment: Economic Geology, v. 72, n. 7, p. 1285-1320.

Environmental Protection Agency, 2015a, Red and Bonita Mine – Removal Action-Bulkhead Plan Summary: May 2015 Microsoft Powerpoint Presentation, 19 p.

Environmental Protection Agency, 2015b, Draft Technical Memorandum, Gold King Mine Investigation and Blowout Event: August, 12, 2015: 64 p.

Environmental Protection Agency, 2015c, Summary Report, EPA Internal Review of the August 5, 2015 Gold King Mine Blowout: August 24, 2015, Summary with Attachments A through F, 23 p.

Klimasauskas, E., Bacon, C., and Alexander, J., 1992, Mount Mazama and Crater Lake: Growth and Destruction of a Cascade Volcano: U. S. Geological Survey Fact Sheet 092-02, 4 p.

Koch, B. C., Hutchinson, R. W., Free, B., and Fogarty, C. F., 1988, Gold Deposition at Gold King, Silverton Caldera, Colorado; in Gold Mining 88: C. O. Brawner (ed.), Society of Mining Engineers, Chapter 35, p. 494-508.

Rosemeyer, T., 1988, History and Mineralogy of the Sunnyside Mine, Eureka Mining District, San Juan County, Colorado: Abstract, New Mexico Bureau of Geology and Mineral Resources, New Mexico Mineral Symposium, November 12-13, 1988.

Schmidt, C., 2012, Field Activities Report; Mine Adit Entry, Red and Bonita Mine Site, Silverton, San Juan County, Colorado: URS Operating Services Inc., U. S. Environmental Protection Agency Contract No. EP-W-05-050, January 20, 2012, 65 p.

Slack, J. F., and Lipman, P. W., 1979, Chronology of Alteration, Mineralization, and Caldera Formation Evolution in the Lake City Area, Western San Juan Mountains, Colorado; in Papers on Mineral Deposits of Western North America: J. D. Ridge (ed.), Nevada Bureau of Mines and Geology Report, n. 33, p. 151-157.

Steven, T. A., and Lipman, P. W., 1976, Calderas of the San Juan Volcanic Field, Southwestern Colorado: U. S. Geological Survey Professional Paper 958, 35 p.

Thompson, J., 2015, The Nitty Gritty Context Behind the Gold King Mine Animas River Spill and the Sunnyside Mine: August 13, 2015.

Way, S., 2014, Approval and Funding for a Removal Action at the Red and Bonita Mine Site in San Juan County, Approximately Seven Miles North of Silverton, Colorado: U. S. Environmental Protection Agency, Action Memorandum, September 24, 2014, 16 p.

Related Articles:

Anatomy of the Gold King Mine Spill – Was it Caused by an Ice Plug?

U of A Says Gold King Mine Will Have No Effect On Lower Colorado River

Disclaimer – David F. Briggs is a geologist, who has worked in the mining industry for more than 35 years.

Copyright © (2015) by David F. Briggs. Reprint is permitted only if the credit of authorship is provided and linked back to the source.